Difference Between CAN and UDS Protocols in Automotive Systems: A Comprehensive Guide

Explore the in-depth differences between CAN and UDS protocols in automotive systems. Understand their functionalities, applications, and how they interact within vehicle networks.

📘 Introduction to the Difference Between CAN and UDS Protocols

When you’re working deep in the world of automotive systems — debugging code, configuring ECUs, or analyzing a vehicle’s electronic behavior — two protocols inevitably show up on your radar: CAN and UDS. At first glance, they might seem like just another pair of technical standards. But once you’ve worked on real vehicles or diagnostics, you realize they’re the silent engines driving modern communication inside a car.

CAN is that reliable workhorse — carrying critical signals every millisecond, keeping things running smoothly. UDS, on the other hand, is more like a skilled technician — it steps in when something goes wrong or when systems need to be updated, tested, or fine-tuned.

They may operate in the same network, but their roles are completely different — one handles day-to-day communication, while the other is your gateway to diagnostics and control. Understanding how they differ isn’t just theory — it’s knowledge that empowers engineers, programmers, and technicians to build smarter, safer, and more efficient vehicles.

In this guide, we’re not just comparing CAN and UDS — we’re unpacking their real-world significance, layer by layer, so you can walk away with clarity, confidence, and practical insight.

🚗 Understanding the CAN Protocol

📌 What is CAN?

The Controller Area Network (CAN) is a robust vehicle bus standard designed to allow microcontrollers and devices to communicate with each other without a host computer. Developed by Bosch in the 1980s, CAN has become a fundamental protocol in automotive systems, enabling real-time communication between various Electronic Control Units (ECUs).

🔍 Key Features of CAN

- Multi-Master Architecture: Any node can initiate communication, allowing for decentralized control.

- Message-Based Protocol: Communication is based on messages rather than addresses, enhancing flexibility.

- Error Detection and Handling: Built-in mechanisms ensure data integrity and system reliability.

- Priority-Based Arbitration: Messages are assigned priorities, ensuring critical data is transmitted promptly

🧱 CAN Frame Structure

A standard CAN frame consists of:

- Start of Frame (SOF): Indicates the beginning of a message.

- Identifier: Determines the priority of the message.

- Control Field: Specifies the size of the data field.

- Data Field: Contains the actual data being transmitted.

- CRC Field: Used for error checking.

- Acknowledgment Field: Confirms successful receipt of the message.

- End of Frame (EOF): Marks the end of the message.

🛠️ Applications of CAN

- Powertrain Control: Engine and transmission management.

- Chassis Control: ABS, ESP, and suspension systems.

- Body Electronics: Lighting, windows, and seat control.

- Infotainment Systems: Audio, navigation, and telematics.

🛠️ Exploring the UDS Protocol

📌 What is UDS?

Unified Diagnostic Services (UDS) is a diagnostic communication protocol used in automotive ECUs, specified in the ISO 14229 standard. UDS provides a standardized method for diagnostic communication, enabling functions such as reading fault codes, programming ECUs, and performing system tests.

🔍 Key Features of UDS

- Diagnostic Communication: Facilitates reading and clearing of Diagnostic Trouble Codes (DTCs).

- ECU Reprogramming: Supports software updates and reprogramming of ECUs.

- Security Access: Implements security measures to prevent unauthorized access.

- Session Control: Manages different diagnostic sessions for various operations.

🧱 UDS Service Structure

UDS services are categorized into:

- Diagnostic and Communication Management Services: Session control, security access, and communication control.

- Data Transmission Services: Reading and writing data by identifier or memory address.

- Stored Data Transmission Services: Accessing diagnostic trouble codes and event memory.

- Input/Output Control Services: Controlling and monitoring I/O signals.

- Remote Activation of Routine Services: Initiating specific routines within the ECU.

🛠️ Applications of UDS

- Vehicle Diagnostics: Reading and clearing fault codes.

- ECU Programming: Updating software and firmware.

- System Testing: Performing component and system-level tests.

- Security Management: Ensuring secure access to vehicle systems.

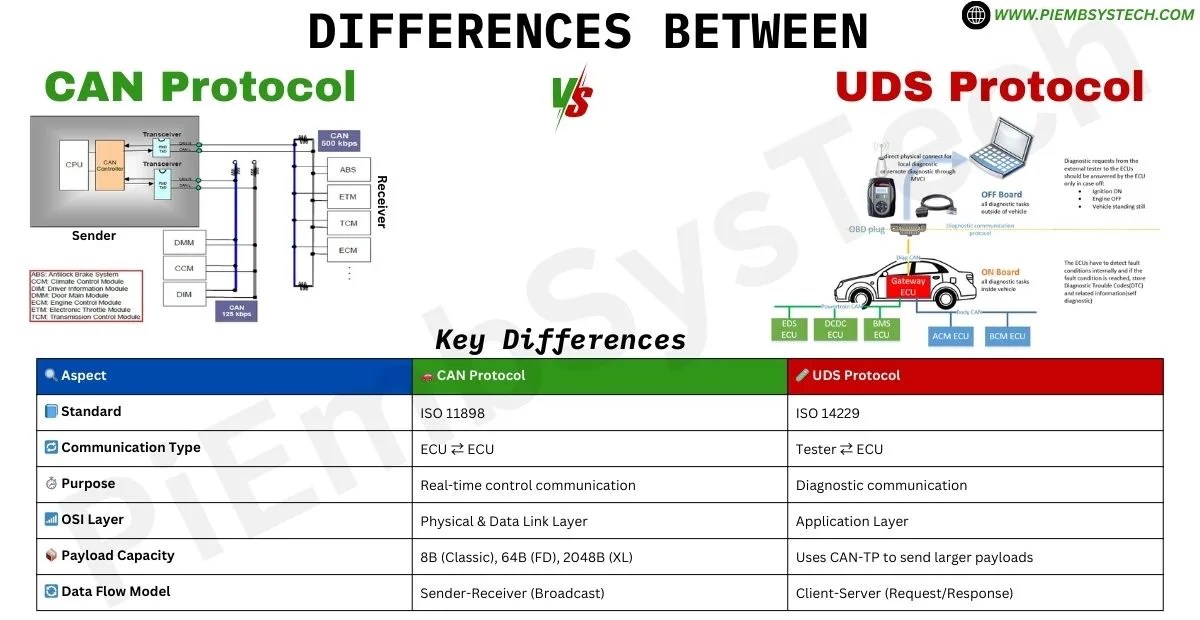

🔄 Comparative Analysis: CAN vs. UDS

| Aspect | CAN Protocol (Controller Area Network) | UDS Protocol (Unified Diagnostic Services) |

|---|---|---|

| Purpose | Real-time communication between ECUs. | Diagnostic communication and ECU programming. |

| Standardization | ISO 11898 Standard | ISO 14229 Standard |

| OSI Model Layers | Physical & Data Link layers (Layer 1 & 2). | Application layer (Layer 7) via CAN-TP (Layer 4/5). |

| Communication Type | Message-based, multi-master, broadcast. | Client-server, request-response over CAN or FlexRay. |

| Payload Capacity | 8 bytes (CAN 2.0), 64 bytes (CAN FD), 2048 bytes (CAN XL). | Up to 4095 bytes using ISO-TP segmentation. |

| Transport Protocols | None inherent; direct over CAN. | Uses ISO-TP (ISO 15765-2) over CAN or Ethernet. |

| Error Handling | CRC, error frames, retransmissions, bus-off. | Negative response codes, session-specific errors. |

| Security | Minimal by design; vulnerable without extra layers. | Security Access Services, session-based authentication. |

| Session Management | Not applicable. | Full session control (default, extended, programming, etc.). |

| Message Prioritization | Arbitration via message ID (lower ID = higher priority). | No internal prioritization; relies on CAN layer. |

| Diagnostic Capabilities | Limited; not designed for diagnostics. | Rich diagnostic set: DTCs, routines, reprogramming, etc. |

| Data Transmission | Broadcast to all nodes; ECUs filter messages. | Targeted communication to specific ECUs (physical or functional). |

| Addressing Mechanism | Identifier-based; no addressing. | Functional & physical addressing supported. |

| Bandwidth | 1 Mbps (CAN 2.0), 8 Mbps (CAN FD), 20 Mbps (CAN XL). | Relies on transport; supports CAN FD and future protocols. |

| Implementation Complexity | Moderate; mature ecosystem, extensive tools. | Higher; needs UDS stack, diagnostic strategy. |

| Scalability | Excellent across automotive and industrial domains. | Good for diagnostics, less suited for real-time operations. |

| Real-Time Performance | Excellent, deterministic. | Not suitable for real-time needs. |

| Security Vulnerabilities | DoS attacks via error injection; spoofing possible. | Session hijacking, weak authentication risks if poorly implemented. |

| Tooling and Ecosystem | Widely available, affordable, open-source options. | Requires OEM-specific tools (e.g., Vector, ETAS, etc.). |

| Learning Curve | Moderate; well-documented with global standards. | Steep; requires in-depth understanding of diagnostics. |

| Use in Other Industries | Automotive, industrial automation, aerospace, medical. | Primarily automotive (diagnostics and reprogramming). |

| Cost of Implementation | Low to moderate; cost-effective. | Higher; more complex and tool-dependent. |

| Future Outlook | Growing with CAN FD, CAN XL, cybersecure enhancements. | Future integration with Ethernet and cybersecurity modules. |

🔗 Interplay Between CAN and UDS Protocols

While CAN and UDS serve different purposes, they often work in tandem within automotive systems. UDS utilizes the CAN protocol as a transport layer for diagnostic communication. This integration allows diagnostic tools to communicate with ECUs over the existing CAN network, facilitating functions such as fault code retrieval and ECU programming without the need for additional communication infrastructure.

🧠 Conclusion

Understanding the differences and interplay between CAN and UDS protocols is crucial for professionals involved in automotive system design, diagnostics, and maintenance. CAN provides the foundational communication framework for real-time data exchange between ECUs, while UDS offers a standardized approach for diagnostics and ECU programming. Together, they form a cohesive communication ecosystem that ensures vehicle systems operate efficiently and reliably.

Discover more from PiEmbSysTech - Embedded Systems & VLSI Lab

Subscribe to get the latest posts sent to your email.